SideCooler DX

The traditional climate control solution

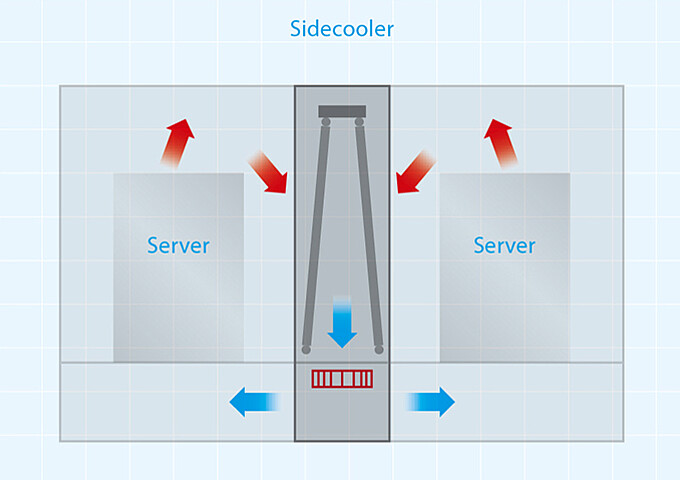

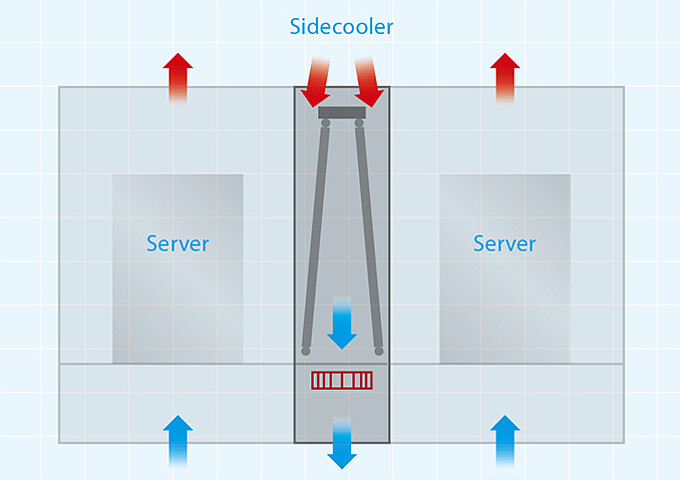

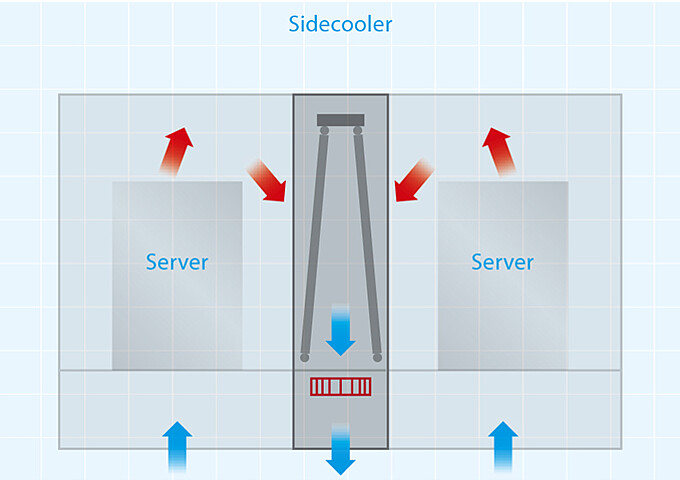

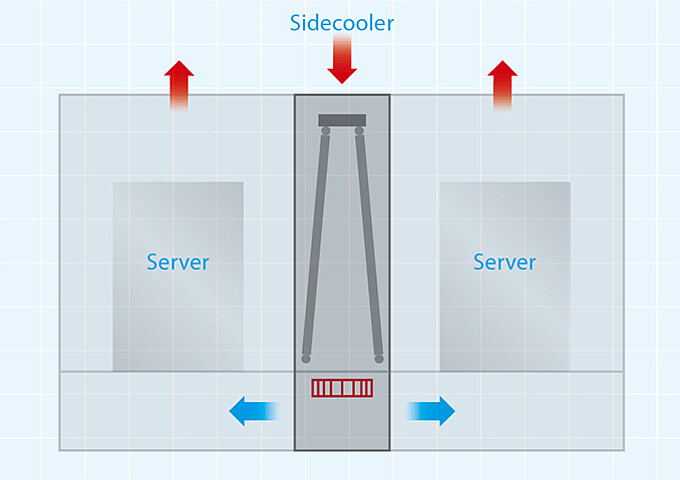

SideCooler DX can operate with coolant and are installed on the side of the rack, placing them especially close to the heat source. Fans can be replaced during operation. From individual rack cooling to bayed suite cooling, the Sidecooler offers maximum application flexibility. This SideCooler can be combined with other cold-water and coolant –based side coolers without any problems.